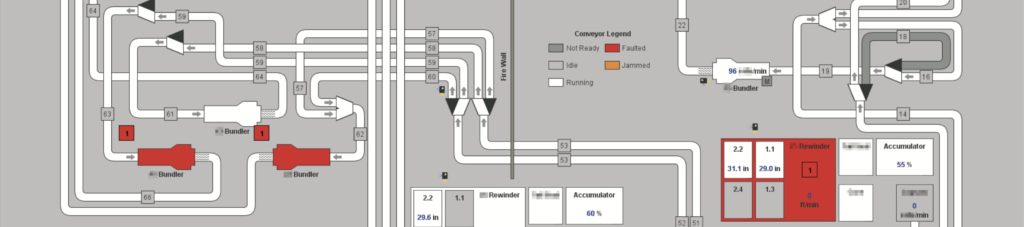

Olsson Industrial Electric completed a project to install a conveyor storage and robot work cell system in the ATI Titanium Foundry in Albany, Oregon. This project involved concept design, engineering and installation of a storage conveyor and robot work cell to process parts through the foundry mold process. The robot work cell was designed to process parts through a slurry dip, sand operation and transfer finished parts to the storage conveyor.

Olsson was the general contractor for this project and was responsible for all engineering (structural, electrical and mechanical) and construction of the system. The Olsson project management team coordinated five subcontractors to facilitate a complete system design from concept to production operation. The system was implemented with the latest controls equipment (Allen Bradley, ABB, Ignition SCADA and Fanuc Robots).