Everything You Need to Know About PLC, HMI & SCADA

At Olsson Industrial Electric, our team is dedicated to becoming apprised of premier industry technologies in order to equip our clients with the highest quality resources on the market. Our goal is the success of our clients; therefore, we seek out, acquire, and become trained in the tools required for our clients to exceed their objectives and rise above their competition.

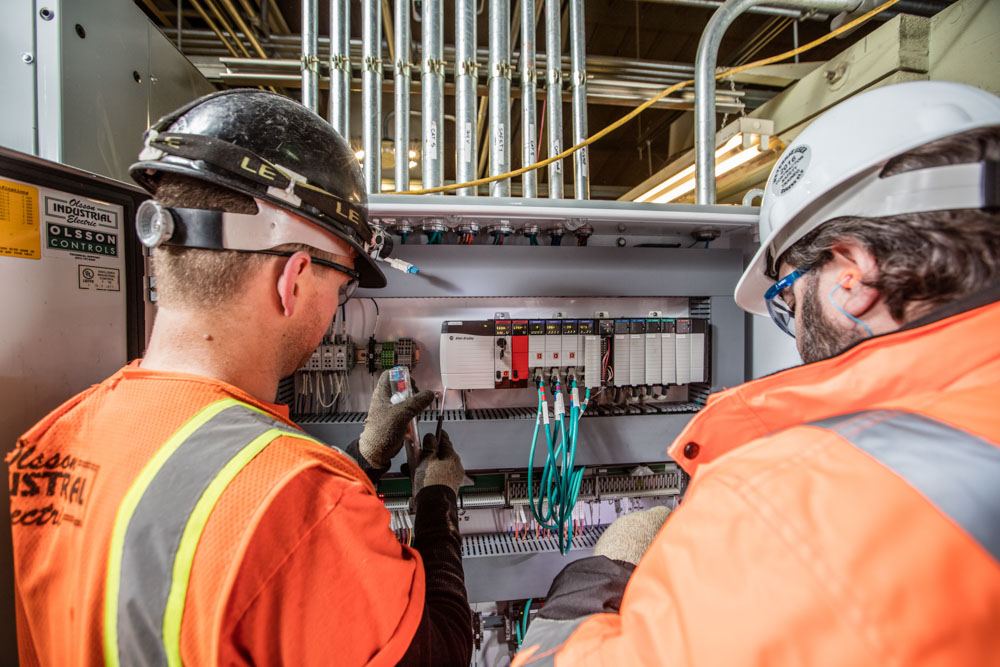

We are proud to offer the utmost in SCADA (supervisory control and data acquisition), from the basic PLC (programmable logic controller) to the complete SCADA system. At Olsson, we are uniquely positioned to offer in-house design, fabrication, and installation for every element throughout a SCADA system, from PLCs and HMIs ((human machine interface) to software and communication networks. While our primary partner in system integrations is Rockwell Automation, our UL 508A-certified panel shop and team of licensed engineers ensures that we are equipped at the highest level to build and install any PLC your facility requires. We have extensive experience with projects spanning a vast range of industries and sizes, from lumber mills to citywide water utilities.

We are available to design and offer support for single PLCs, which are comprised of inputs and outputs measuring facility conditions and activating threshold responses. The use of a single PLC, communicating information through a series of simple lights and push buttons, is most ideal for extremely small-scale, single-machine, low-budget projects and rugged environments with variable temperatures. Most facilities are transitioning to the use of a comprehensive SCADA system, which incorporates an HMI and allows each PLC throughout a facility or system to communicate within a localized software program.

Our team is well-versed in programming HMI visualization platforms to synthesize and communicate information in a way that is most conducive to that particular operation and functionality. Through our design strategies, we work to avoid information overload, presenting only the information that is needed, and making that information accessible from as many points as possible. Another advantage to using HMI software is that it is easily adaptable. It is much more convenient to expand functionality through a software program than it is to perform physical PLC changes. HMI systems do require ongoing licensing costs in order to undergo necessary software upgrades—but the benefits of streamlining overall operations vastly outweigh the reasonable costs of HMI maintenance.

A SCADA system encapsulates every PLC and HMI, integrating each element so that the PLCs can be controlled and information can be analyzed through a single, localized platform. A SCADA system may also include radio, cellular, and/or fiber optic communication networks. We are proud to be Premier Integrators for Inductive Automation’s industry-leading Ignition software. While we do utilize additional hardware platforms, we encourage clients to standardize across the company in order to optimize daily operations and maintenance. Our team is seasoned in partnering with industrial clients to standardize SCADA systems according to their particular needs, sometimes in phases to alleviate budgetary concerns. We are proud to have a track record of little-to-no downtime and extremely satisfied customers. Contact us today to find out how we can assist your facility in modernizing, renovating, and upgrading your PLC and SCADA systems to keep up with industry standards.